Taking Advantage of IoT and Industry 4.0 in a Practical Manner

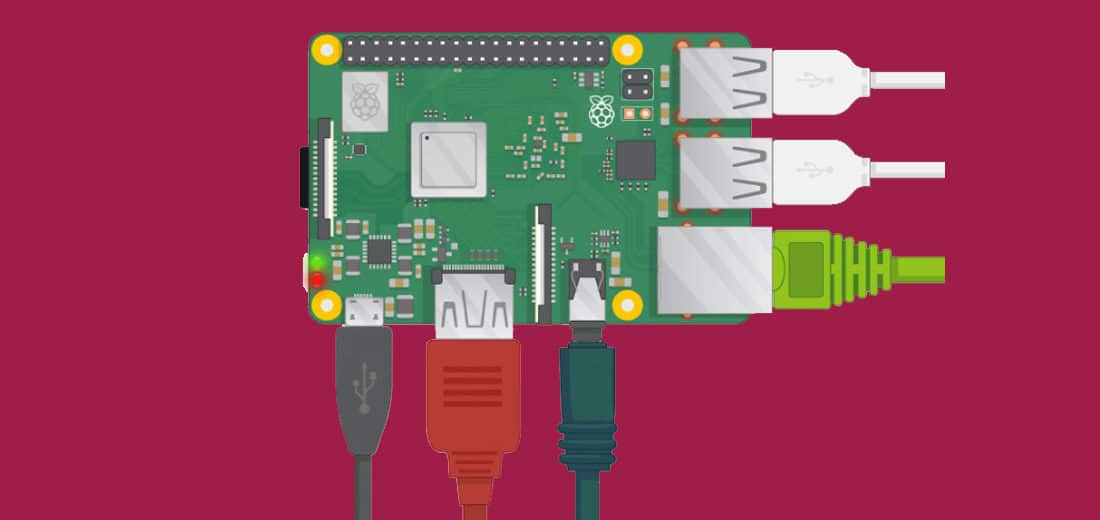

That’s not a typo, or a misspelling, or a reference to a waistline-expanding treat: According to its website, “Raspberry Pi” is the name of “a small and affordable computer that you can use to learn programming.” Over the past few years I’ve been having some fun looking at how to adapt Raspberry Pi for both home and industrial applications. Often thought of as a controller replacement (which it can certainly be), the Raspberry Pi is also an interesting tool because it allows for simple connectivity for communication and data collection. I wanted to share with you some of the personal and professional applications I’ve developed.

I purchased an older house a number of years ago and made a number of “interesting” discoveries: one of the most annoying was that my outdoor lights were controlled by a single light switch located in the far-end of my garage. Because I have to walk across the entire house, often down several flights of stairs, I was never turning them on and coming home in the dark. So I decided to use a Raspberry Pi to allow me both manual and automated control of my outdoor lights.

Stealing some late night hours, I quickly cobbled together some code, (found a couple of primers on how to control lights via a webpage and via an infrared sensor), and bread boarded up a couple of LEDs to simulate my outdoor lights. It took some thought and tinkering, but I made it work.

So why do I bring this all up on our blog? Well, it was a really fun project that I got into. I have a bunch of ideas about how I want to continue to build it out and enhance it. But more importantly, I think it helps to highlight some of the capabilities and applications of ‘alternative’ controllers in the manufacturing space.

Certainly if you’re facing environmental constraints, performance requirements, lots of I/O, etc., you are going to want to stick with your traditional kinds of controllers. But if you need to pick up a few I/O for data purposes or interact with the web or data, or develop other small and non-critical types of applications, the Raspberry Pi and other devices of its ilk represent a great alternative. They have a lot of capabilities, they’re easy to use and program, and are easily replaceable from a reliability / maintainability perspective.

For example, I recently spoke with a customer who was looking to do some checking on packaging material to ensure the right product was ending up in the right package. They were looking at some scanner solutions that could handle all detection and signaling of an issue, but they needed to be provided with the proper barcode and other related order information. In the past we may have utilized a small PLC to handle the Ethernet communications to and from the scanners and handle some of the signal processing coming out of them. The scanning devices had on-board relays that could be wired to the existing control system to stop conveyance or annunciate a mismatch, etc., so we only needed to solve for the communication from an existing scanner and some database queries. This was a perfect chance to use a Raspberry Pi to bridge that gap. A traditional small PLC that would have cost many orders of magnitude more. Other customers have used an inexpensive Raspberry Pi to handle remote sensing of temperature readings or run InTouch Machine Edition for data connectivity. All of these are proof that having a Raspberry Pi loaded and ready to go on standby provides for a simple and cheap business continuity solution.

What about you? Have you used any of these ‘alternative’ solutions in your environments? Where do you feel they might be the most applicable? Let us know by filling in the response form below.

For more information about how Avanceon provides innovative automation solutions, click here

Image Source: raspberrypi.org