PLCs for the DIYer: Perfect for when you can’t get enough automation at the office

At Avanceon we are always looking to try new tools and innovate in all we do. This is not limited to when we are “on the clock”. Our homes are often another area where we look to apply our skills learned in the manufacturing world to make our life easier (or at least cooler and a topic for conversation). While each of us can’t likely afford a top of the line Rockwell PLC for simple home automation, I have found low cost options that can allow me the ability to automate and control a number of functions in my home.

For that purpose, the CLICK PLC by Automation Direct offers automation capabilities at a fraction of the price of other brands. Many small tasks are perfect for simple PLC control. Whether it’s turning lights on and off, controlling a fan or turning on a sprinkler, Click PLCs can provide the ideal control solution without breaking your budget. In school, I used one of these PLCs for my senior project to control a custom fabricated machine that a team and I designed. CLICK PLCs start at just $69 for a basic CPU with two RS-232 ports and built in I/O. I chose to go with the $129 Ethernet model for easier communication with a computer. Add on cards are also very inexpensive, ranging in price from $33 to $59 for DC I/O and $89 and $149 for analog cards. So, for less than $200 you have a lot of options and power to play with.

So it’s cheap, but what does it offer?

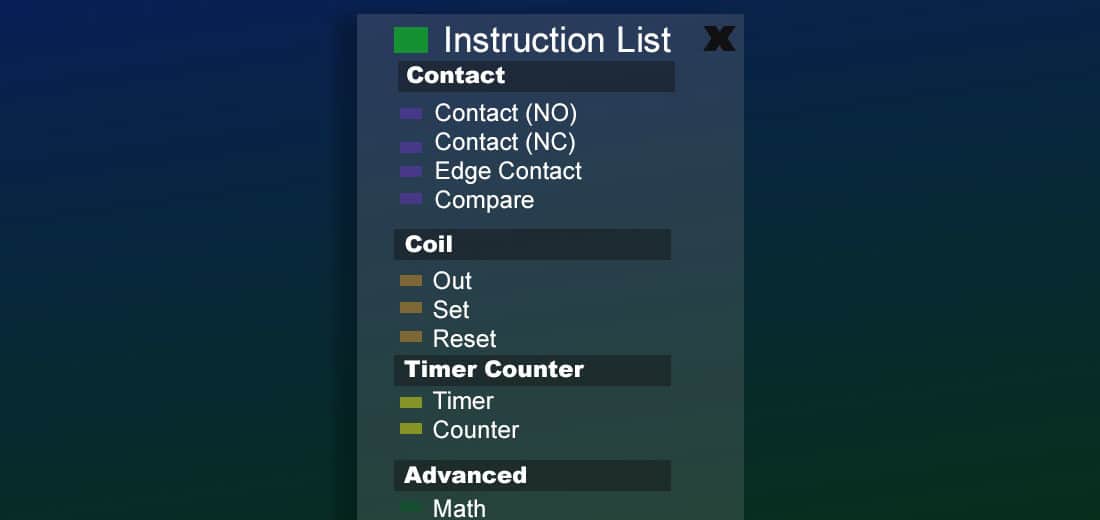

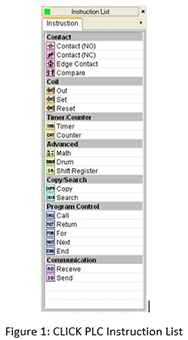

The programing software has all the basic functionality one would expect from a PLC. Information is called from and stored in data locations, which can be viewed in the program’s Address Picker. As is typical for PLCs, programing is done in a ladder logic format using a set of instructions placed on rungs. The 21 instruction types can be seen in figure 1. The software provides enough instructions to handle the majority of basic on/off, math, subroutine, and communication needs.

In practice, the CLICK PLC’s simplicity makes the learning curve low. It’s very easy to learn, even for someone who has never used a PLC. Addressing is straightforward: place an instruction and pick a location of appropriate data type (or port.) All locations can have a nickname assigned to them, which appear in the program. Rungs can also have descriptions added to them. In practice, it feels like a scaled back SLC 500.

I would describe the build quality on the CPU and its modules as good. It’s no Allen Bradley, but the build quality is good enough that I would feel comfortable putting it in any home-built machine. I checked the PLC, power supply, and 4 DC I/O cards for functionality upon receiving them. I tested all 78 I/O ports found them to all be in working order. I know this was something I should expect — but one can never be too sure at these prices.

The amount of support provided for this PLC is a huge bonus. The specification sheets for the PLC and its modules are simple and present the end user with all relevant information. There are also a slew of videos available from Automation Direct to get you started and if there is something that you can’t figure out, there are countless more videos from other users on YouTube. Automation Direct also offers a free online class to buyers of their PLCs. These classes give the user a more in- depth understanding of its functionality.

Shortcomings

While the CLICK PLC is an incredible tool for individuals who want to do their own automation, it does have some drawbacks. The biggest drawback for most people would be the limited number of instructions available in the software.

For my senior project, I used the CLICK PLC to control a custom fabricated machine for automating part of the process of cutting out long bows for archery. The process included controlling stepper motor drivers, monitoring limit switches, operating relays, accepting user inputs (push button), and displaying status and set points on an HMI. For the most part, the CLICK PLC handled what I needed it to, quite well. There were a few exceptions, however.

I had three main issues with the CLICK PLC First was that it did not have any high speed output cards (or instructions) available. This was an issue for the TB6600 stepper motor driver that I used, since it operates the motor based on a pulse input. In other words, one pulse to the input of the driver from the PLC equates to a single rotation step on the motor. As part of the project, I controlled of lead screws via stepper motors with the PLC. This limited the speed of the motors to 150 RPM, which made for very slow movement with the finer-threaded lead screws. However, this posed a significant price increase over the TB6600 drivers that I used.

My second issue with the CLICK PLC was its programming software’s lack of dynamic addressing capabilities for data locations. This became a significant issue when I was pulling data pertaining to set points. In short, there were 160 set points that were each located in their own integer data location. Which two set points someone would use, was determined from two different parameters set by the user on the HMI. Ideally, the conditions for which data locations were referenced would be determined in a single line, but I used 160 of these rungs to pull data from the set points and the other 160 to program data to the set points when they needed to be changed. While this method had the desired effect, it was cumbersome and inelegant to say the least.

My third issue was the lackluster, or lack of, monitoring and online editing ability. The CLICK PLC uses a tool called “data view” to read and write values in memory addresses while online. While it works fine, all locations you wish to edit must first be added to the tool. This can be time consuming, if you need to add something after you have already begun troubleshooting. It’s important to emphasize that this is the only way to . The software will change into offline edit if you try to change any values in any other way, including toggling Boolean bits. This brings up the next point: there are no online edits in the CLICK software. NONE. Any changes made to the program must be done offline and re-downloaded to the PLC. This can make troubleshooting on the CLICK PLC incredibly time consuming.

Final Thoughts

While the CLICK PLC does have some shortcomings, it stands out as an incredible bang for the buck. Could it be used in industrial applications? No, of course not, but it has great potential for prototyping and for hobbyists. However, anyone who wishes to use this PLC, should first familiarize themselves with its limitations and ensure that they will not inhibit integration into their project.

Avanceon engineers are always encouraged to experiment, play, and grow. To learn more about our corporate culture, click here.