When you compare the lifespan of a cell phone or a laptop to that of a PLC or I/O module the difference is impressive. PLC’s and similar control system components last decades longer than our everyday electronics. Their cost to value to lifespan ratio equates to an amazing return on investment (ROI). But, just like Luke Combs says in his song “Forever After All” – “When the new wears off, and they get to getting old, sooner or later, time’s gonna take its toll”.

Everything has a limit and the impact of computer component progression, supply chain problems, and source code support issues eventually catch up to even the most reliable PLC systems. PLC’s and PC’s, just like your phone, eventually become obsolete.

At Avanceon, we’ve been designing, developing and supporting control systems for nearly four decades. After all of these years, we have replaced and upgraded systems that we installed in our early years with new models with increased functionality. That commitment to staying fresh with technology drives our efforts in Obsolescence Upgrades.

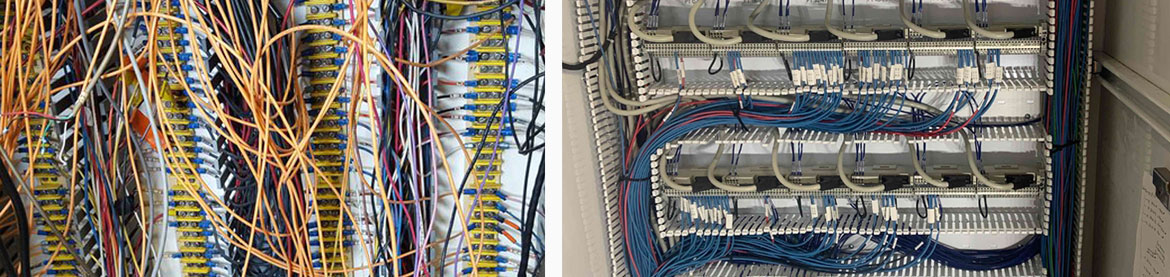

Our Obsolescence Upgrade Process can be tailored to the smallest controller replacement or a full scale, cross enterprise program to “freshen” the outdated technology. We evaluate, assess, determine risk, prioritize, plan, and execute to improve the areas of your business that have become obsolete. Based on those assessments we come up with the best plan to upgrade while minimizing the impact on production and overall cost. Our approach ranges depending on your need; from implementing simple conversions to full rewrite conversions that add new functionality and address gaps in the old system.

Our approach is tailored to your needs. Our execution is grounded in the experience gained from replacing and enhancing thousands of obsolete systems.

We are ready to help you get rid of your old kit. And give it a much needed facelift.

Obsolescence/Upgrade Process

Home / Obsolescence/Upgrade Process